Zahnradpumpe für stark korrosive Flüssigkeiten in der Batterierecycling-Branche

Lithium-Ionen-Akku Recyclinganlage, Batterierecycling

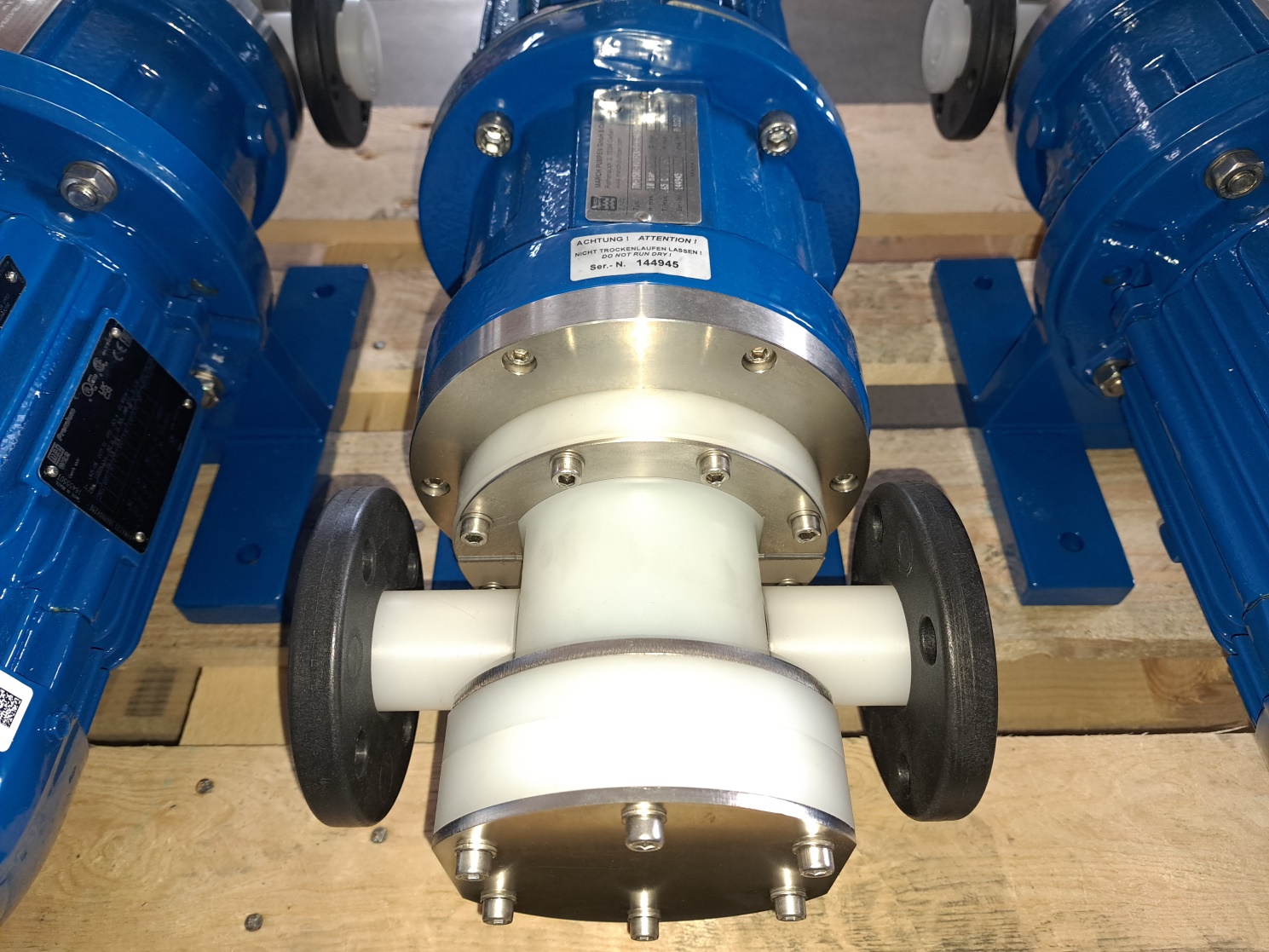

TEF-MAG® - chemikalienbeständige Zahnradpumpen aus komplett nicht-metallischen Materialien für Batterierecycling

MARCH-PUMPEN beliefert weltweit agierende Anlagenbauer für Batterierecyclinganlagen. Insgesamt können so Verarbeitungskapazitäten von mehr als 15.000 Tonnen Elektroauto-Batterien erneut in den Wertschöpfungskreislauf gebracht werden. MARCH-PUMPEN unterstützt so aktiv die Nachhaltigkeit im Umweltschutz, durch den Beitrag zur Vermeidung von Batterie-Restmüll, mit der Produktion und Lieferung der patentierten, chemikalienbeständigen und magnetgekuppelten Zahnradpumpen aus komplett nicht-metallischen Materialien der Serie TEF-MAG®, zum dosieren verschiedenster Säuren und anderer hoch korrosiver Flüssigkeiten.

Im Prozess selbst, werden die Batterien zuerst mechanisch behandelt um die sogenannte „schwarze Masse“ zu erhalten, welche aus den wertvollen Rohstoffen wie Lithium, Kobalt, Nickel und Mangan besteht. Die schwarze Masse wird dann hydrometallurgisch, durch starke Säuren und anderer aggressiver Flüssigkeiten weiterverarbeitet. Dabei werden die Metalle gelöst und in einem speziellen Verfahren separiert.

Hierbei müssen Kleinstvolumenströme der hochkorrosiven Prozessflüssigkeiten von 5-1500 l/h bei Differenzdrücken von 5 bar oder mehr, pulsationsarm dosiert werden.

Die patentierte Zahnradpumpe TEF-MAG® von MARCH-PUMPEN vereint hierbei die gute Dosierfähigkeit von rotierenden Verdrängerpumpen, die chemische Beständigkeit durch den Einsatz von komplett nicht-metallischen Materialien, als auch die Leckagefreiheit durch den Einsatz der Magnetkupplungstechnologie.

MARCH PUMPEN achtet hierbei nicht nur auf die chemische Beständigkeit der medienberührten Teile. Auch Komponenten welche der chemisch aggressiven Atmosphäre ausgesetzt sind, werden speziell ausgewählt oder behandelt. Die Pumpenlaterne wird aus hochwertigem EN-GJS-400-15 hergestellt und komplett nach Korrosionsschutzklasse C5 hoch, nasslackiert. Die Antriebsmotoren werden ebenfalls für die raue Atmosphäre speziell ausgelegt. Eine Vielzahl von Optionen, wie z.B. die VIK Ausführung, spezielle Nasslackierungen, Schrauben, Welle und Typenschilder aus Edelstahl oder sogar das beschichten und behandeln der Wicklungspakete oder des Innengehäuses ist hierfür möglich.

Eingesetzte Pumpentypen

| Gehäuse | PVC und PVDF |

|---|---|

| Wellen | SSiC |

| Zahnräder | PEEK, PVDF und PTFEC |

| Gleitlager | PTFEC und Graphit |

| O-Ringe | FKM und FFKM |

Bildmaterial