Baureihe CODIP

DRUCKLUFTBETRIEBENE ZYLINDERMEMBRANPUMPEN

Stufenlos regelbare, druckluftbetriebene, trockenselbstansaugende, trockenlaufunempfindliche und feststoffsichere*1 Zylindermembranpumpe, medienberührte Teile komplett aus PTFE gefertigt.

Die CODIP- Druckluftbetriebene Zylindermembranpumpe ist eine oszillierende Verdrängerpumpe, bei dem das Medium in einem zweifachen Zylindermantel für optimale Sicherheit untergebracht ist. Das Fördermedium ist von einer ummantelten Innertflüssigkeit umgeben. Dies führt zu einer sanften Förderung und Verteilung der Kräfte über den gesamten Zylindermantel und damit zu optimalen Standzeiten auch unter schwierigen Einsatzbedingungen. Der Betrieb der Pumpe mit Stickstoff, als Antriebsmedium ist grundsätzlich möglich. Dies erfordert eine vollständig geschlossene und isolierte Umgebung mit ausreichender Belüftung am Aufstellungsort der Pumpe.

CODIP- Zylindermembranpumpen wurden entwickelt, zur Bewältigung schwieriger Förderaufgaben, mit aggressiven abrasiven und explosiven Chemikalien. Viskositäten bis 25.000 mPas, maximalen Medientemperaturen bis zu 180 °C, maximale Förderdrücke bis zu 10 bar (150 psi) ermöglichen ein weites Feld von Anwendungsgebieten, bei der eine sichere Förderung von umweltgefährdenden, toxischen und gesundheitsgefährdenden Flüssigkeiten unter maximalen Sicherheitsbedingungen gewährleistet wird.

Konstruktionsmerkmale

- Leckagefrei

- Selbstansaugend

- Feststoffsicher

- Trockenlaufsicher

- Impulsaustausch mittels Inertflüssigkeit

- Geringe mechanische Belastung der Membrane

- ATEX Version verfügbar

*1 Unterschiedliche Einsatzgrenzen bei unterschiedlichen Baureihen erfragen

Funktionsbeschreibung

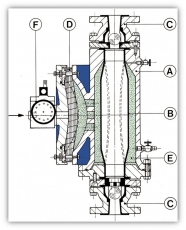

Ein automatisches Luftsteuerventil (F) überträgt den Druck der Antriebsluft auf die Antriebsmembrane (D). Die Antriebsmembrane (D) verdrängt die Innertflüssigkeit (E) welche die Zylindermembran (B) kontrahiert und dabei das saugseitige Kugelventil (C) schließt. Gleichzeitig öffnet das druckseitige Kugelventil (C) und Medium wird in die Druckleitung gefördert. Im Ansaugzyklus geht die Antriebsmembrane (D) selbsttätig in Ihre Ausgangsposition zurück, ein Unterdruck entsteht, die Zylindermembrane (B) entspannt sich. Das druckseitige Kugelventil (C) schließt, das saugseitige Kugelventil (C) öffnet, Fördermedium strömt in den Zylinder.

Technische Daten

| Baureihe CODIP | DNS/D [Zoll BSP] | Qmax [m3/h] | ΔPmin [bar] | ΔPmax [bar] | Luftverbrauch max [m3/min] | Material |

|---|---|---|---|---|---|---|

| RP 20 | 1" | 1,32 | 10 | 0,21 | nicht-metallisch | |

| RP 60 | 2" | 5,88 | 10 | 0,65 | nicht-metallisch | |

| RP 60 DX | 2" | 10,68 | 10 | 1,28 | nicht-metallisch | |

| RP 150 | 3" | 10,8 | 10 | 1,62 | nicht-metallisch | |

| RP 150 DX | 3" | 21 | 10 | 3,2 | nicht-metallisch |

| Förderdruck: | max. 10 bar |

| Systemdruck: | max. 10 bar |

| Temperatur: | -20°C bis 180°C |

| Feststoffe: | 7 mm, 50% vol. |

Anschlüsse

| Flansch: | nach DIN EN 1092-1 |

Medienberührte Werkstoffe

| Zylindermembran: | PTFE, FKM, EPDM, Neoprene, Hypalon |

| Ventilkugeln, Sitze: | PTFE, FKM, EPDM, Neoprene, Hypalon |

Anwendungen

- Entsorgung unbekannter / undefinierbarer Chemikalien

- Probenahmen

- Viskose, abrassive, korrosive Flüssigkeiten

- Umwelt- und Gesundheitsgefährdende Flüssigkeiten

- Säuren, Laugen, Lösungsmittel, Flüssiggase

- Ultrareine Medien in der Pharmazie