Magnetic Drive Chemical Centrifugal Pumps

PRODUCT SPECIFICATION

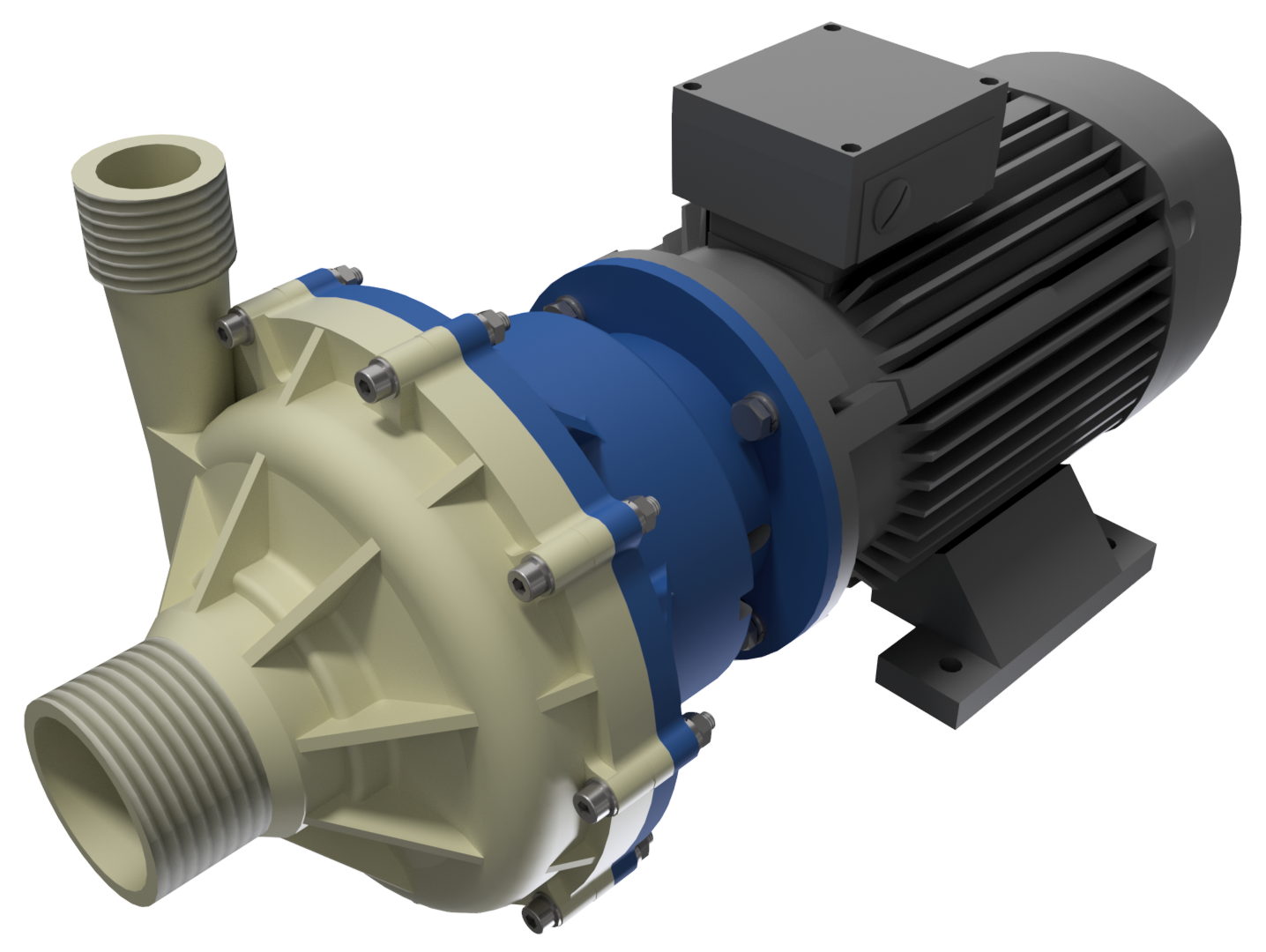

EUROLINE series: The most economical solution for safe and leak-free pumping of aggressive, explosive and environmentally hazardous liquids.

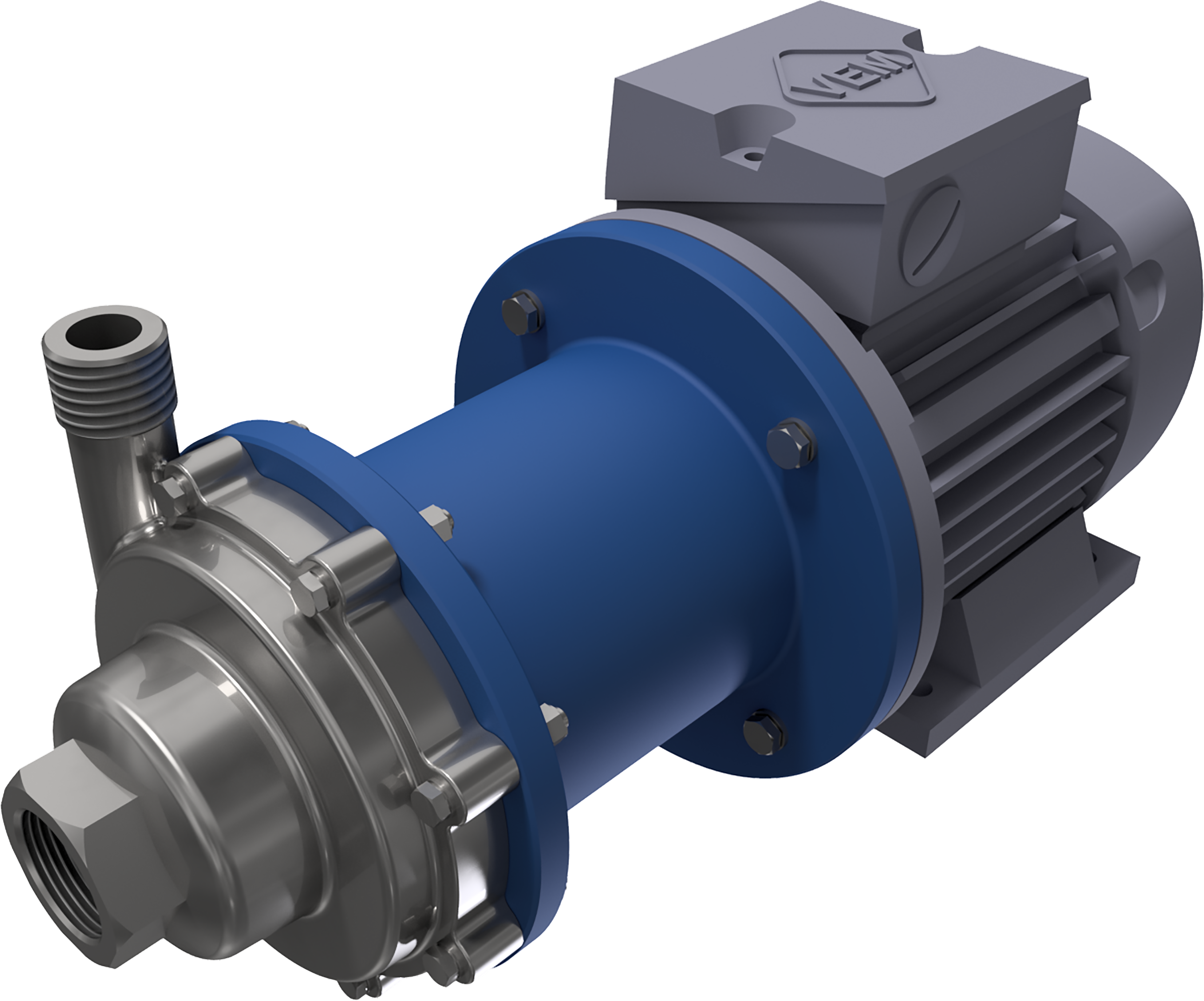

M series: Providing outstanding durability and robustness when pumping hazardous and aggressive liquids, even in explosive areas.

MARCH magnetically driven centrifugal chemical pumps operate entirely without mechanical shaft sealing. The power is transmitted to the hydraulic part by a forced-lock connection using permanent magnets without contact. MARCH magnetically coupled centrifugal chemical pumps comply with the highest standards regarding quality, economy and reliability for pumping aggressive, toxic and environmentally hazardous liquids.

FEATURES:

- Centrifugal pump / Turbomachine

- Maintenance-free

- Leak-free

- Modular concept

- Magnetically coupled, Seal-less

- Only for pure fluids free of solids

- Normal suction

- Housing made of plastic injection molding

- Corrosive resistant materials

- High quality motor types

TYPE / FUNCTION:

The pumps are designed in a compact modular concept. The modular building system enables the individual parts to be replaced quickly without the need for special tools. The pumped liquid provides the lubrication of the sleeve bearings. This means that the pumps are maintenance-free. Operation without pumped liquid (dry running) and liquids containing particles must be avoided. Only IEC norm motors according to DIN/EN 60034 and VDE 0530 are used as motors. All pumps of the M series can be supplied with either threaded or flanged connections. The application limits, in particular the minimum flow rate and the required inlet head (NPSH , erf.) must be observed to ensure smooth pump operation without malfunctions.

APPLICATIONS:

MARCH magnetically driven centrifugal chemical pumps are used particularly for the safe pumping of acids, alkalis and solvents. Proven application examples include their use as filter pumps in galvanic technology, the printed circuit board industry, as filling and circulation pumps in the chemical industry and in apparatus construction, as well as food, pharmaceutical and biotechnology.

TECHNICAL DATA:

| Flow rate | M1 max. 8 l/min up to M10 max. 40,5 m³/h |

| Discharge head | M1 max. 4 mWs up to M10 max. 35 mWs |

| System pressure | PP max. 2,5 bar, PVDF max. 3,5 bar, PPS (Ryton®) max. 3,5 bar, POM (Delrin®) max. 3,4 bar |

| Temperature | PP max. 70°C, PVDF max. 90°C, PPS (Ryton®) max. 70°C, POM (Delrin®) max. 90°C |

| Density | Max. 1,8 kg/dm³ |

| Viscosity | Max. 150 cP |

MATERIALS:

| Housing | PP, PVDF, POM, PPS |

| O-Ringe | EPDM, FKM, NBR, FFKM, PTF |

| Shaft | Ceramic, Stainless steel, Hastelloy C |

| Sleeve bearings | Carbon, RTC, PTFE |