MCH series

MAGNETICALLY DRIVEN CENTRIFUGAL CHEMICAL PUMPS

Horizontal, normal suction, single-stage, magnetic driven chemical standard pumps in close-coupled or process design made of stainless steel or wetted pump parts made of non-metallic materials also according to ATEX 2014/34/EU.

Magnetically driven centrifugal pumps of the "MCH" series are made of rugged solid block material in polypropylene or PVDF. They work completely without mechanical shaft seal and are therefore leak-free. The power is transmitted by a forced-locked connection without contact through strong permanent magnets on the hydraulic part. The sliding bearing material used is exclusively PTFEC. The pump shaft is made of high-purity oxide ceramics (99.7%) as standard. These manufacturing features ensure utmost service life and optimum corrosion resistance. Magnetically coupled centrifugal pumps of the "MCH" series meet the highest demands in terms of safety and reliability when pumping the most aggressive, toxic and environmentally hazardous liquids.

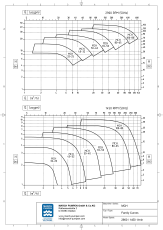

Technical Data

| MCH series | Qmin [m3/h] | Qmax [m3/h] | Hmin [mWs] | Hmax [mWs] | Speed [1/min] | Materials |

|---|---|---|---|---|---|---|

| MCH 32-25 | 1,25 | 11 | 4 | 15 | 2900 | non-metallic |

| MCH 40-32 | 1,75 | 17,5 | 5 | 22 | 2900 | non-metallic |

| MCH 50-40 | 3,3 | 30,5 | 7,5 | 26 | 2900 | non-metallic |

| MCH 65-50 | 5 | 46 | 8 | 35 | 2900 | non-metallic |

| MCH 80-65 | 8 | 92 | 9 | 36,5 | 2900 | non-metallic |

| MCH 100-80 | 16 | 132 | 7 | 44 | 2900 | non-metallic |

Connections

Flanged acc. to. DIN 2501

Materials

Housing: PP, PVDF

O-Ring: EPDM, FKM, FFKM

Bearings: PTFEC

Pump shaft: Al2O3 99% Ceramic

Operating limits

System pressure: max. 10 bar

Temperature: PP max. 80 °C, PVDF max. 90 °C

Density: max. 2,0 kg/dm³

Viscosity: max. 250 cP

Applications

Magnetically driven "MCH" series centrifugal pumps have been used successfully for many years wherever aggressive liquids must be pumped safely and without leaks. For example for the extraction of acids, alkalis or solvents in:

• Chemical industry

• Electroplating

• Wastewater treatment

• Chemical storage facility

• Power plant technology

• Plant engineering