Dosing pump for wastewater neutralization

Wastewater neutralization

TEF-MAG® - chemical resistant gear pumps made of completely non-metallic materials for pumping acids and alkalis

Wastewater neutralization plants are equipment used to treat and neutralize wastewater before it is released into the environment. These plants are typically used in industrial plants, factories, hospitals, laboratories, and other facilities that generate large amounts of wastewater. Neutralizing wastewater is important to ensure that the wastewater is not harmful to the environment. Untreated wastewater can contain a variety of harmful substances such as heavy metals, organic chemicals, oils and greases, and pathogens and other pollutants. Wastewater neutralization uses a combination of chemical and physical processes to adjust the pH of the wastewater and remove pollutants. Various processes are used for this purpose, such as neutralization reactors, sedimentation plants, filtration devices, flocculation and other technologies. Selecting the right wastewater neutralization plant depends on several factors, such as the type of wastewater, the amount of wastewater produced, the degree of contamination, the pH of the wastewater, and environmental requirements. Most wastewater neutralization plants are designed to operate automatically and are continuously monitored to ensure that the treated wastewater meets prescribed standards and does not harm the environment. Overall, wastewater neutralization plants are an important part of environmental protection measures and play a critical role in reducing pollution and maintaining water quality.

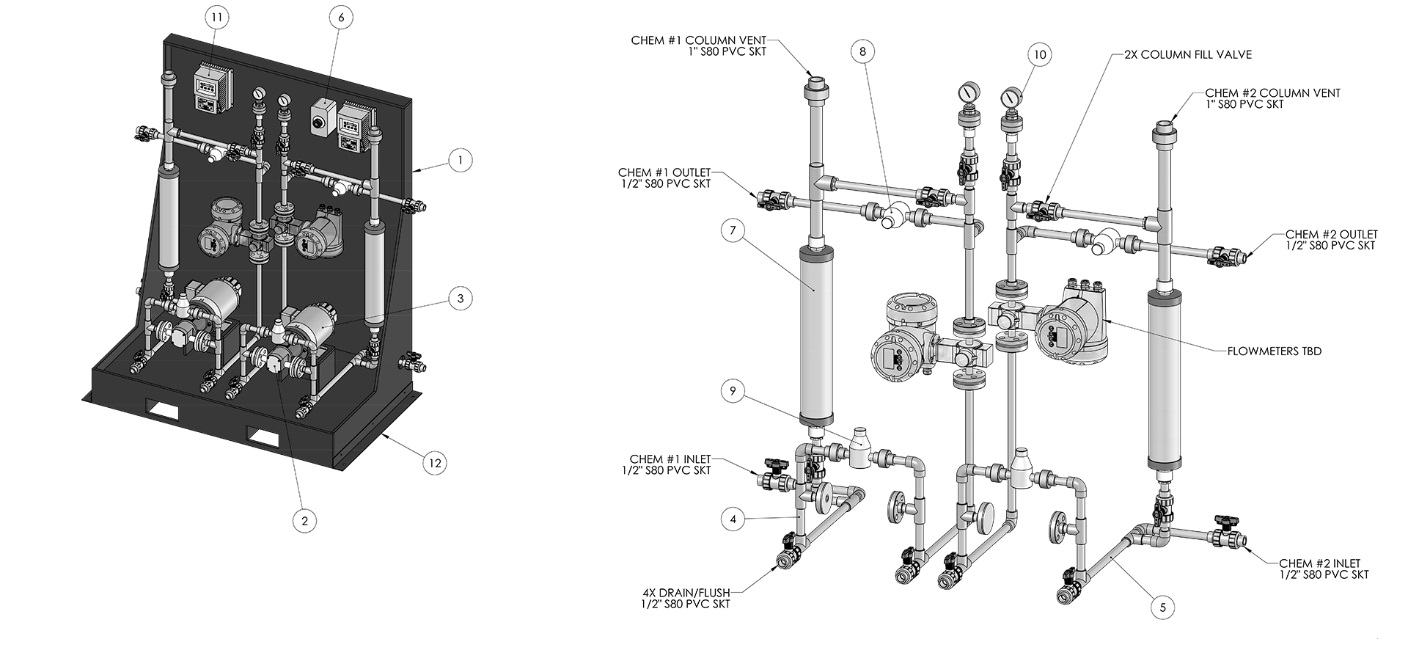

The magnetically coupled and corrosion-resistant external gear pumps of the TEF-MAG® series are installed for this purpose by OEMs or plant engineers in so-called metering skids, which are then delivered turnkey to the end users.

Another application of a neutralization plant is in brine mining, in which NaCl brine is extracted by flushing out the solid salt with water from salt deposits at depths of 350-700m. The crude brine is shipped to appropriate processing plants for further processing to produce edible and feed salts, medicinal salts and other products such as soda ash production and chlorine-soda production. However, during the production of the raw brine, some caverns may have an excessively high pH of about 11. To address this, a process-controlled dosing of HCI hydrochloric acid 30% is used through a piping system with a March pump to neutralize to a pH neutral value of approximately 7. This process ensures that the quality of the raw brine meets the required standards. The dosing of HCI Hydrochloric Acid 30% has proven to be an effective method of PH neutralization and contributes to the company's ability to produce high quality products.

Chemical wastewater treatment uses a variety of fluids to remove pollutants and contaminants in wastewater. Here are some of the common liquids:

- Precipitants: Precipitants such as calcium hydroxide (lime), aluminum sulfate or ferric chloride are used to remove phosphates, sulfates, heavy metals and other contaminants. The addition of these chemicals creates insoluble particles that settle in the wastewater and can then be removed.

- Acids: Acids such as hydrochloric acid or sulfuric acid are used for pH regulation and neutralization of wastewater. Especially in the case of alkaline wastewater, the addition of acids can lower the pH value and neutralize the wastewater.

- Alkalis: Alkalis such as sodium hydroxide or calcium hydroxide can be used for pH regulation and neutralization of acidic wastewater.

- Oxidizing agents: Oxidizing agents such as hydrogen peroxide or potassium permanganate can be used to break down organic compounds such as hydrocarbons, dyes or pesticides in wastewater.

- Reducing agents: Reducing agents such as sodium bisulfite can be used to remove chlorine from wastewater.

- Activated carbon: Activated carbon is used to adsorb organic compounds in wastewater.

- Ozone: Ozone is used to disinfect wastewater because it can effectively kill bacteria and viruses.

The selection of suitable liquids for chemical wastewater treatment depends on the type and amount of pollutants contained in the wastewater. It is important that the liquids are used carefully, taking into account the environmental impact.

Pictures