Gear Pump made of PVC in Saltwater desalination systems

Sodium Chlorite Handling with the TEF-MAG® Gear Pump – Corrosion-Resistant, Rugged & Efficient

Einleitung

a leading manufacturer of desalination plants in Turkey, was searching for a reliable solution for pumping and handling highly concentrated Sodium Chlorite (NaCl, brine, brine solution, salt brine). Due to the high corrosion requirements and the necessity of a durable, low-maintenance system, the choice fell on the chemically resistant TEF-MAG® gear pump from MARCH PUMPEN.

What Are Desalination Plants?

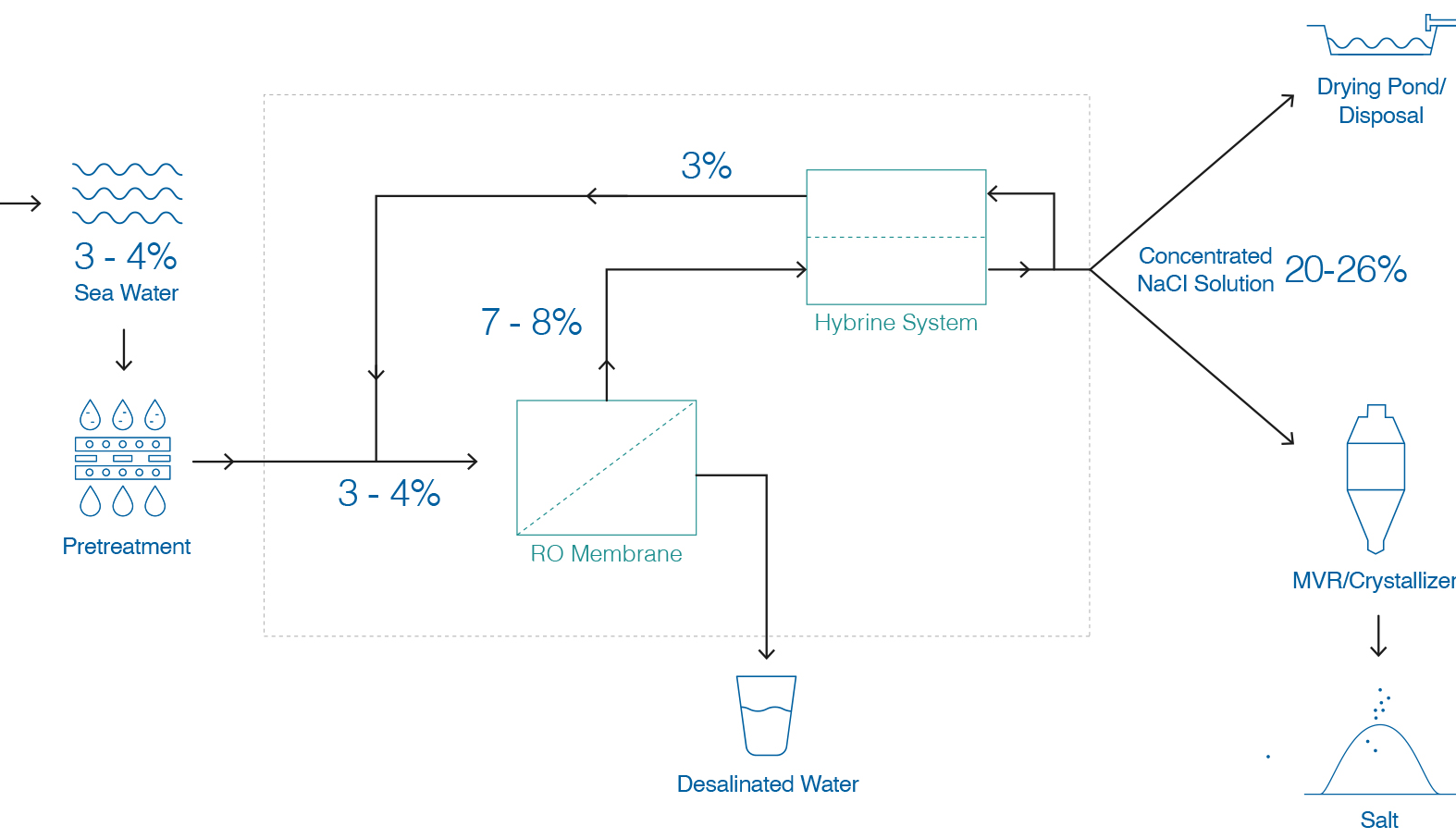

Desalination plants are used to remove salt from seawater or brackish water to produce drinking water or industrial process water. This technology is especially crucial in regions with water scarcity. Using advanced processes such as reverse osmosis or thermal distillation, salt is extracted from the water, making it drinkable. In addition to water treatment, the process also presents the potential to integrate the extracted salt into material management as a byproduct. It can be further utilized in industrial applications, chemical production, or the food industry, promoting a sustainable resource cycle.

The Challenge

Seawater desalination imposes stringent requirements on the pumps used. The pumped brine is extremely aggressive, and conventional metal pumps are prone to corrosion and wear. Hyrec needed a solution that:

- Offers high chemical resistance to concentrated NaCl

- Requires minimal maintenance and ensures long service life

- A Pump which can handles small flow rates at high differential pressure (500 – 1200 l/h at 8 bar differential pressure)

The Seawater Desalination Process

Seawater desalination is carried out in multiple stages, where pumps play a crucial role:

- Seawater Intake – The raw water is pre-filtered to remove coarse impurities.

- Pretreatment – Chemicals such as antiscalants are added to prevent deposits in the reverse osmosis membranes.

- Reverse Osmosis (RO) – Water is forced through special membranes at high pressure, removing salt and impurities.

- Brine Handling with the TEF-MAG® Gear Pump – The resulting concentrated brine must be efficiently discharged. Due to the high salt concentration, Hyrec uses the TEF-MAG® pump, as it is corrosion-resistant, low-maintenance, and energy-efficient.

- Further Processing and Brine Disposal – The brine is processed to extract valuable minerals.

- Drinking Water Treatment – The purified water is further treated, remineralized, and prepared for consumption.

The solution: TEF-MAG® non-metallic gear pumps

The TEF-MAG® Gear Pump is specifically designed for demanding applications in the chemical industry. Its non-metallic design and the magnet drive offer crucial advantages:

- High Chemical Resistance: No corrosion thanks to non-metallic materials. In this case, both the TEF-MAG 800 and TEF-MAG 1500 models made of PVC were used.

- Leak-Free Design: The mag drive construction of the TEF-MAG eliminates the risk of leaks. This is especially important when handling aggressive media that could damage the system in case of leakage.

- Precision and Reliability: Gear pumps enable a precise and nearly pulsation-free flow at a constant pressure, which is beneficial for most processes, particularly applications with low flow rates and high discharge pressure.

- Efficient and Durable Solution: Reduced maintenance effort and longer operating times.

The MARCH TEF-MAG® gear pump is the ideal solution for demanding applications in water treatment and the chemical industry. The chemical resistance, reliability, and efficiency of the TEF-MAG® series have proven to be decisive advantages for Hyrec. This makes it an excellent choice for companies seeking safe and long-lasting pumping technologies under the most challenging and corrosive industrial conditions.