Solvent Metering Pump for PVE Production

Solvent dosing for the production of Polyvinylether

VANE-MAG® MPA - corrosion-resistant and magnetically-coupled rotary sliding vane pumps made of stainless steel for dosing solvents.

Polyvinyl ether is produced by the polymerization of vinyl monomers, in which a large number of vinyl groups are linked together to form a long polymer chain. There are various methods for producing polyvinyl ether, but the most common method is the radical polymerization of vinyl methyl ether (VME) or vinyl methoxy methyl ether (VMME).

The polymerization occurs in the presence of an initiator, which triggers the formation of radicals that then bind the monomers. The reaction can be carried out in an aqueous or organic solution or in a melt.

The steps for producing polyvinyl ether are as follows:

- Production of VME or VMME by reacting vinyl chloride with methanol or methoxy methanol.

- Polymerization of VME or VMME by radical polymerization in the presence of an initiator such as hydrogen peroxide or benzoyl peroxide.

- Separation of the polyvinyl ether by filtration, drying, or extraction.

The resulting polyvinyl ether polymer has a high molecular weight, is soluble in water and organic solvents, and exhibits good thermal and chemical stability. It is used in various applications such as a binder, additive in the paper and textile industry, coating of metal surfaces, and in the production of adhesives.

The VANE-MAG® pump is used in this application as a dosing pump for the solvent N-ETHYL-2-PYRROLIDONE >= 98% (NEP).

N-ethyl-2-pyrrolidone (NEP) is used as a solvent in the production of polyvinyl ether (PVE). It is a polar, aprotic solvent that has high solvency for PVE. NEP is often used as an alternative to other solvents such as dimethylformamide (DMF) or dimethylacetamide (DMAc), which are increasingly regulated due to their potential toxicity and environmental impact.

NEP allows for the dissolution of PVE in a solution, which can then be used for the production of coatings, adhesives, fibers, and other applications. It is also used in the cleaning of PVE equipment and for the extraction of PVE from polymer blends or solutions.

It is important to note that NEP is also a potentially hazardous solvent and should be handled and used with care.

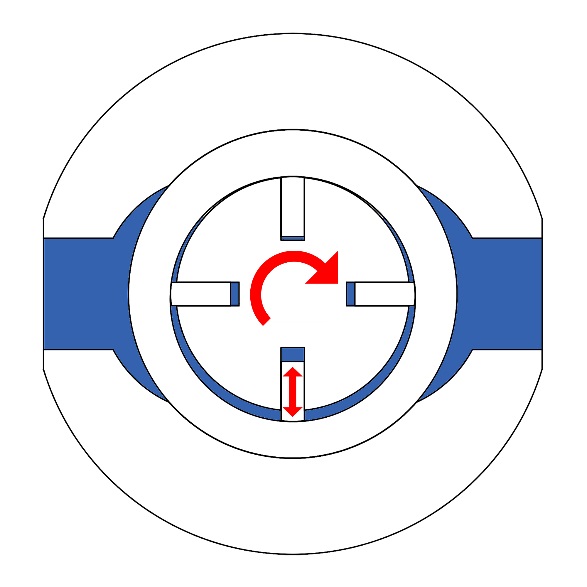

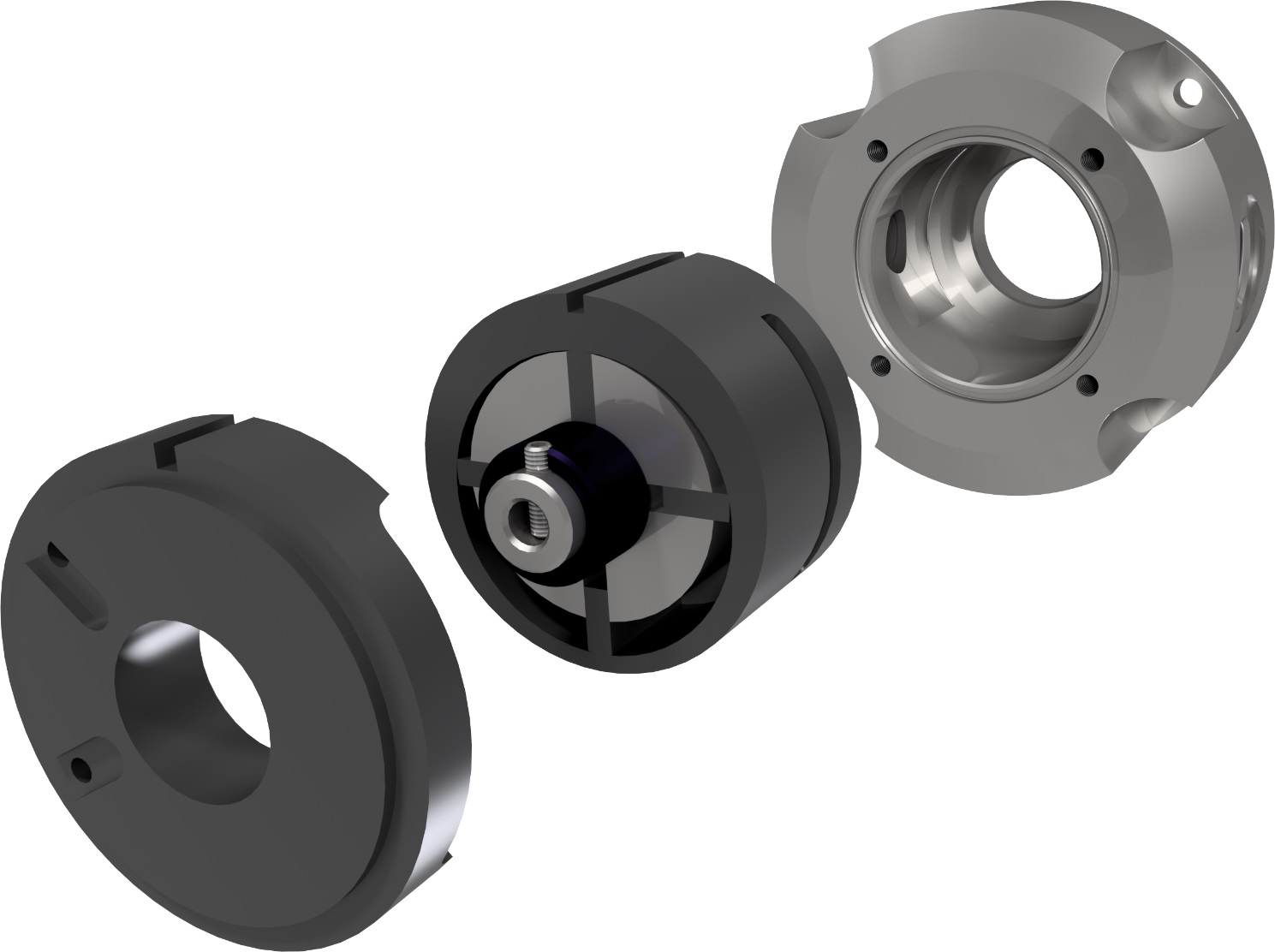

The VANE-MAG® MPA magnetically coupled rotary sliding vane pumps have the advantage of having particularly effective hydraulics. These rotating positive displacement pumps are typically used to pump or dose fluids with low lubricity. The rotor of the pump is machined with slots in which the vanes move radially and press against the inner wall of the stator bore. In this way, a narrowing space is created between the vane and stator during the rotation of the rotor, which sucks in the medium. As the vane is further moved, the medium is trapped between the vane and housing and conveyed to the outlet of the pump by the rotation of the rotor. The vanes, stator, and axial bearing are made of carbon graphite and have very good self-lubricating properties.

Rotary vane pumps are often used in applications where pulsation-free and continuous pumping of small quantities at high backpressure is required, such as in the chemical, food, and pharmaceutical industries. They are maintenance-free and have a long service life, as they consist of few parts that do not wear easily under ideal operating conditions.